Freeze-drying fruit at home preserves its vibrant flavors and nutritional value while creating delightful snacks that can last for months. While commercial freeze-dryers are expensive specialized machines many people seek alternative methods to achieve similar results in their own kitchens.

Freeze-drying fruit without a machine involves using a combination of your regular freezer and careful temperature control to remove moisture through sublimation. This process typically takes 1-2 weeks and requires minimal equipment including a freezer baking sheets and mesh racks.

Traditional freeze-drying methods might take longer than machine-based approaches but they’ll help preserve fruit’s natural sweetness and create crispy lightweight snacks perfect for hiking trail mix or everyday enjoyment. Understanding the science behind moisture removal and temperature control unlocks the potential for successful DIY freeze-drying.

“1. Pre-freeze fruit pieces

Pre-freezing creates the foundation for successful freeze-dried fruit. The process starts with thorough cleaning of fresh fruit under cool water to eliminate dirt or residue.

Preparation steps:

- Clean fruits thoroughly under cool water

- Pat dry with paper towels

- Remove peels from fruits like bananas or apples

- Cut large fruits into uniform pieces (¼ to ½ inch thick)

- Leave small fruits like blueberries whole

- Line baking sheets with parchment paper

- Arrange fruit pieces in a single layer

- Keep pieces separated to prevent sticking

- Place sheets in freezer at lowest temperature setting

- Position trays away from other frozen items

The size uniformity affects the freeze-drying results – smaller, evenly-sized pieces freeze more consistently. A single layer arrangement promotes proper airflow around each piece, creating optimal conditions for moisture removal during the freeze-drying process.

| Fruit Type | Recommended Size | Preparation Method |

|---|---|---|

| Berries | Whole | Leave intact |

| Bananas | ¼ inch | Peel and slice |

| Apples | ½ inch | Core and slice |

| Strawberries | Halved/quartered | Hull and cut |

2. Place in vacuum chamber

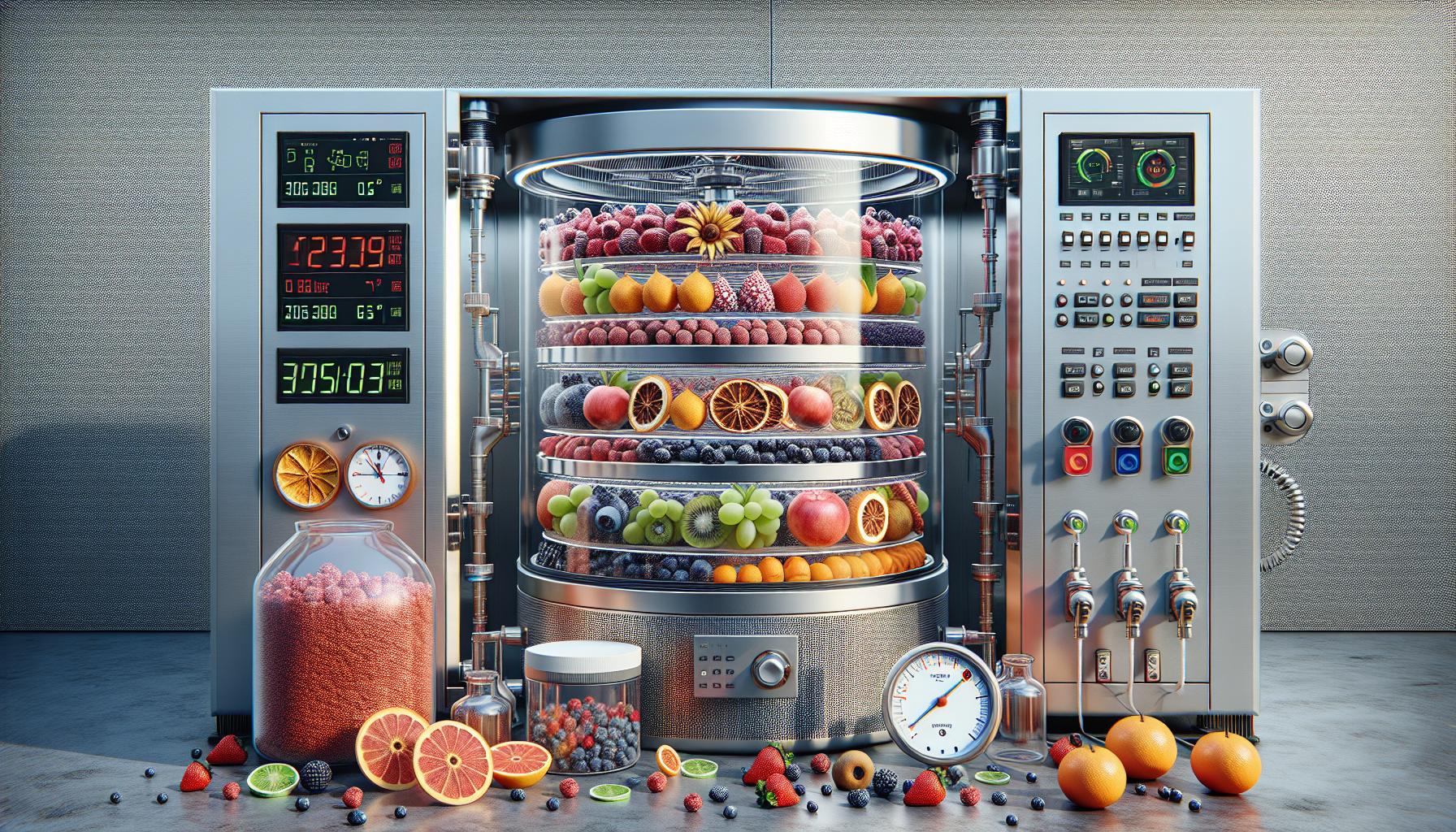

The vacuum chamber method creates an environment that accelerates moisture removal from frozen fruit. After placing the pre-frozen fruit pieces on mesh racks, transfer them to a vacuum chamber set at -40°F (-40°C). Position the racks with adequate space between pieces to optimize airflow.

Three essential steps for vacuum chamber placement:

- Set chamber pressure to 300-400 millitorr

- Place temperature sensors in direct contact with fruit

- Monitor chamber humidity levels at 15-20%

| Fruit Type | Vacuum Time | Target Pressure |

|---|---|---|

| Berries | 8-12 hours | 350 millitorr |

| Stone Fruit | 12-16 hours | 325 millitorr |

| Citrus | 10-14 hours | 375 millitorr |

The chamber’s vacuum pump removes air molecules while maintaining freezing temperatures. This dual action transforms ice directly into vapor through sublimation. Leave fruit in the chamber until moisture content drops below 2% for optimal preservation.

3. Add desiccant packets

Desiccant packets play a vital role in absorbing excess moisture during the freeze-drying process. Place 2-3 food-grade silica gel packets around the frozen fruit pieces on the baking sheet. The packets maintain optimal dryness by pulling residual moisture from the air inside the freezer.

For effective moisture absorption:

- Position packets 2-3 inches apart from fruit pieces

- Replace packets every 48-72 hours

- Use only food-grade desiccants labeled safe for food contact

- Store used packets in an airtight container for reuse

| Fruit Type | Desiccant Packets Needed |

|---|---|

| Small Berries | 2 packets per tray |

| Sliced Fruit | 3 packets per tray |

| Large Pieces | 4 packets per tray |

Monitor the desiccant packets for color changes that indicate saturation. Clear or blue packets turn pink or purple when saturated with moisture. Replace saturated packets immediately to maintain consistent moisture absorption throughout the freeze-drying cycle. Keep spare packets sealed in an airtight container between uses to preserve their absorption capacity.

4. Maintain vacuum 24-48 hours

A stable vacuum creates optimal conditions for freeze-drying fruit through sublimation. The vacuum chamber requires constant monitoring of pressure gauges maintaining 300-400 millitorr. Digital sensors track temperature staying at -40°F (-40°C) while humidity levels stay between 15-20%.

Key monitoring points:

- Check pressure readings every 4 hours

- Monitor temperature sensors touching fruit surfaces

- Replace saturated desiccant packets when color changes

- Inspect fruit texture for complete drying

- Document vacuum readings in a log

The ideal vacuum duration varies by fruit type:

| Fruit Type | Vacuum Time |

|---|---|

| Berries | 24-30 hours |

| Stone Fruit | 36-42 hours |

| Citrus | 40-48 hours |

A consistent vacuum pressure transforms ice directly into vapor without liquid formation. Fruit moisture content drops below 2% when properly dried. Temperature fluctuations or vacuum leaks extend drying time significantly. Opening the chamber during the process disrupts sublimation creating ice crystals that damage cell structures.

5. Store in airtight containers

“

Proper storage ensures freeze-dried fruit maintains its crispy texture for 6-12 months. Place the completely dried fruit pieces in food-grade glass jars or mylar bags with airtight seals. A moisture content test confirms readiness – the fruit breaks with a snap instead of bending when properly dried.

Storage essentials:

- Glass mason jars with rubber-sealed lids

- Mylar bags with oxygen absorbers (1-2 per bag)

- Food-grade desiccant packets (2-3 per container)

- Vacuum sealer for mylar bags

Place the containers in a cool dark location at 65-70°F (18-21°C). Label each container with:

- Fruit type

- Freeze-drying date

- Expected expiration (12 months from processing)

Check containers monthly for:

- Moisture buildup on container walls

- Changes in fruit texture or color

- Desiccant packet saturation levels

Transfer contents to new containers immediately if moisture appears. Monitor humidity levels using indicator cards placed inside each storage vessel for optimal preservation.